Features

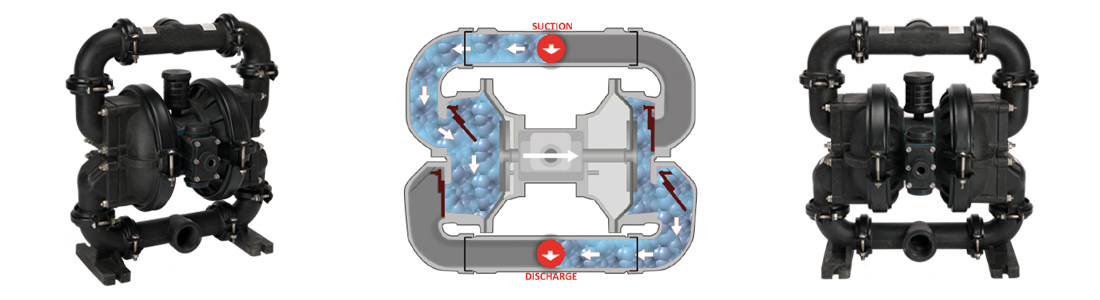

- Flap valve pump can handle solid parts virtually at the same size of the suction port

- Non-metallic construcion (GFPP body)

- Suitable for liquids which contain large and irregular particles

- Top-suction / bottom-discharge design to easily handling of solid parts: the gravity force helps to keep clean the flap valves

- Advanced and efficient air valve

- Self priming and dry run ability without damage

- Easy access to the flap valve (bolted cover valve for a rapid inspection)

- In line maintenance without removing the pump from installation

- Clamped construction for a quick disassembly

- Good abrasion resistance

- Main applications: slaughtering, mining , steel mill, livestock farm, waste water treatment

Technical Data

| Max Capacity: | 550 l/min |

| Max Head: | 7 bar |

| Max Suction Lift – Dry Condition: | 4,5 m (Rubber Diaphragm) |

| 3 m (PTFE Diaphragm) | |

| Max Suction Lift – Wet Condition: | 6 m (Rubber Diaphragm) |

| 4,2 m (PTFE Diaphragm) | |

| Max Viscosity: | 6.000 cps (mPas) |

| Temperature Limits: | 0 ÷ 79 °C (PP) |

| -10 ÷ 100 °C (PVDF, SS, AL) | |

| Max Particle Size: | 45 mm |

| Air Inlet Pressure: | 3 ÷ 7 bar |

| Suction Port: | 2” BSP Flanged / Threaded |

| Discharge Port: | 2” BSP Flanged / Threaded |

| Air Inlet Port: | ½” BSP Threaded |

Wetted Parts Material

Polypropylene

| Model | Body | Diaphragm | Flap Valve | Valve Seat | O-Ring |

| PTT | GFPP | PTFE + Neoprene | PTFE | GFPP | PTFE |

| PST | GFPP | Santoprene | PTFE | GFPP | PTFE |

| PHT | GFPP | Hypalon | PTFE | GFPP | PTFE |

| PNN | GFPP | Neoprene | Neoprene | GFPP | Neoprene |

| PBN | GFPP | Buna | Neoprene | GFPP | Neoprene |

Notes:

- The above data refer to a positive suction head operating with water at room temperature.

- All the information indicated may vary without notice.